AI is revolutionizing how buildings are designed, built, and managed. Today’s construction environments are becoming increasingly data-rich, allowing artificial intelligence to transform the way we track progress, ensure quality, and manage virtual models. From intelligent monitoring systems that identify deviations in real time, to AI-integrated workflows that streamline digital fabrication and enable predictive decision-making in VDC, the construction site is evolving into a high-tech ecosystem of precision and foresight.

Smarter Oversight with AI in Construction Monitoring

AI-powered site monitoring brings intelligence to every corner of a project. High-resolution cameras, drones and IoT sensors stream live data to centralized platforms where machine learning algorithms analyze visual and spatial information against project models. These systems can flag unauthorized changes, detect safety risks, and identify work that doesn’t match the digital twin.

For example, a building team might schedule routine 3D scans of an active site. These scans are automatically analyzed by AI software to measure concrete volume poured, flag framing inconsistencies, or assess installation of MEP systems. Rather than relying solely on manual inspections, teams receive instant reports with tolerance deviations and progress percentages. This allows project managers to take immediate corrective action, preventing costly delays.

By incorporating weekly monitoring into a project’s lifecycle, AI ensures that real-time conditions are constantly aligned with design intent. Quality assurance becomes predictive rather than reactive. Teams can compare data across phases, monitor trade-specific completion rates, and even receive alerts when the project timeline deviates from plan. In short, AI construction monitoring introduces a proactive layer of visibility and control that empowers everyone from superintendents to stakeholders.

Precision Building through AI-Driven Digital Construction and Fabrication

AI is also transforming how building components are fabricated and assembled. Whether through robotic systems, 3D printing technology, or digital workflows integrated into prefabrication facilities, artificial intelligence enables unprecedented precision and efficiency.

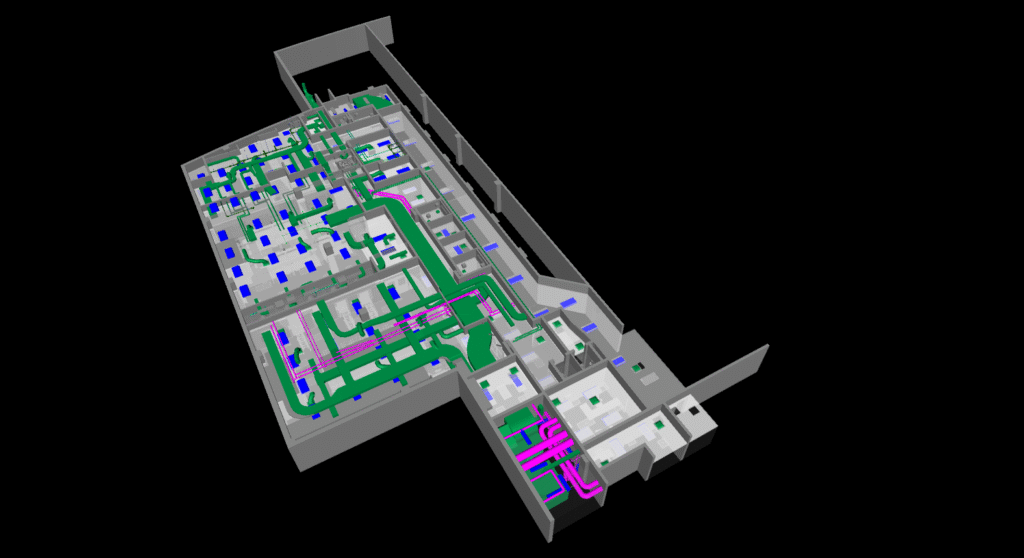

Take the generation of shop drawings, for instance. Instead of manually drafting dozens of documents, teams can use AI-enhanced BIM models to generate fabrication-ready plans within minutes. The same models can feed into automated cutting machines or coordinate field layout points with millimeter accuracy. Every component, from structural steel to complex MEP assemblies, can be digitally designed, verified, and sent to production with minimal human input.

In a prefabrication setting, AI-driven systems can monitor quality during production, identifying flaws or misalignments in real time. This reduces waste, increases consistency, and allows crews to build with confidence once components arrive on site. On the construction site itself, teams might use mobile scanners or drones to confirm that prefabricated elements are installed correctly, comparing the built environment back to the digital model.

Ultimately, AI-enabled digital construction and fabrication bridges the gap between design and execution. It enables tighter coordination between teams, enhances build quality, and reduces the number of surprises during installation. For firms focused on speed, precision, and sustainability, these tools are quickly becoming indispensable.

Elevating Project Coordination with AI in VDC Management

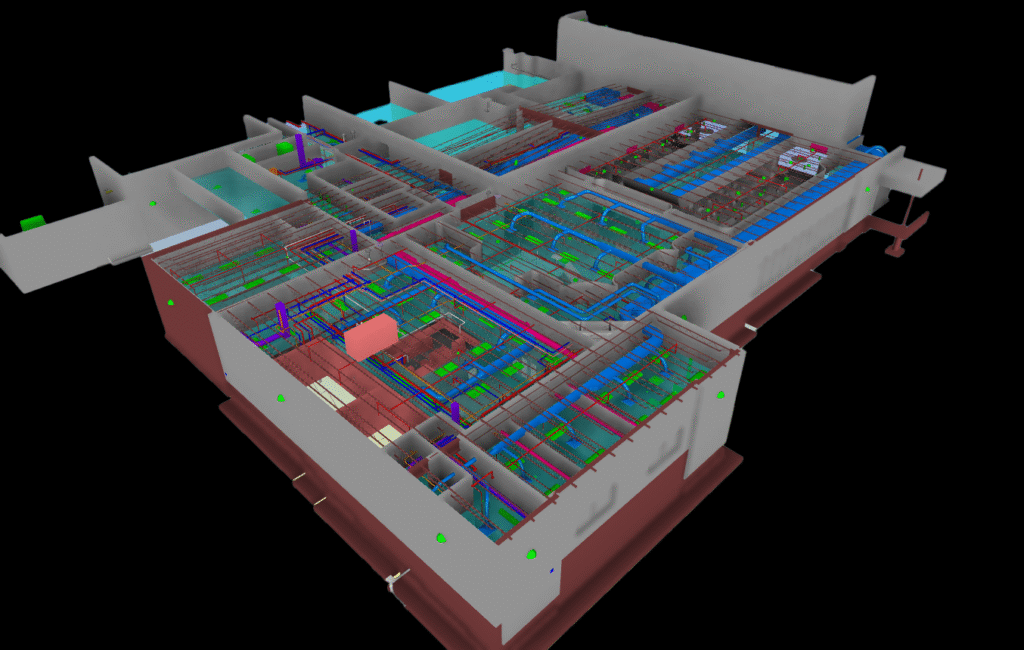

Virtual Design and Construction (VDC) serves as the nerve center of modern building projects, and AI is now a critical component of its evolution. AI-powered tools help VDC teams track model integrity, ensure alignment between schedules and designs, and manage risk at scale.

Imagine a workflow where 4D models are constantly updated based on real-time scan data. AI algorithms highlight deviations between planned and actual construction sequences, identify which elements are lagging, and even simulate alternative phasing scenarios. This makes it possible to anticipate schedule conflicts before they happen and adjust logistics accordingly.

AI can also enhance issue tracking and coordination. Instead of manually logging every clash or deviation, automated tools scan the BIM model and site conditions to create prioritized issue lists. These are shared across platforms so architects, engineers, and contractors stay aligned.

Perhaps most powerfully, AI supports decision-making. By aggregating performance data across multiple projects, systems can suggest optimal construction sequences, predict which design elements are most likely to create coordination problems, and model how changes in one area affect time and cost elsewhere.

When integrated into a full VDC workflow, AI ensures that digital coordination isn’t just a one-time effort, but a living process. With better oversight, improved communication, and data-driven planning, project teams can navigate complexity with greater confidence.

Book a free 30-minute consultation with Voyansi to explore how we can support your next AI-powered construction project: